The Snapmaker 2.0 is an innovative all-in-one machine designed for makers who want to explore a variety of creative disciplines. It combines three different tools—3D printing, laser engraving/cutting, and CNC carving—into a single modular device. Whether you’re a hobbyist, a professional maker, or a small business owner, the Snapmaker 2.0 promises to be an adaptable, space-saving solution. In this review, we’ll delve into its performance, key features, strengths, and drawbacks to help you determine if it’s the right machine for your needs.

Overview of Snapmaker 2.0 Models

The Snapmaker 2.0 comes in three main models: the A150, A250, and A350. These models differ mainly in their working area and price, catering to different user needs and budgets.

- A150: The most compact and affordable option with a 160 x 160 x 145mm build volume.

- A250: A middle-ground machine with a larger 230 x 250 x 235mm build volume.

- A350: The largest model, with an expansive 320 x 350 x 330mm workspace for bigger projects.

All models share the same core features, including modular design, interchangeable tool heads, and a user-friendly interface. The model you choose depends on the scale of your projects and available workspace.

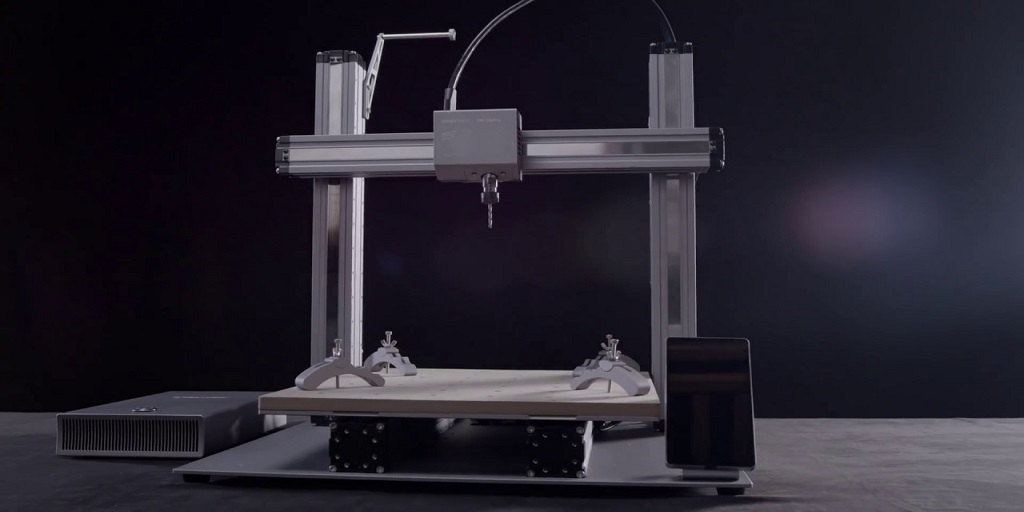

Design and Build Quality

Snapmaker 2.0’s modular design is one of its standout features. The machine is constructed from high-quality aluminum alloys, giving it a solid and professional look and feel. The metal frame not only makes it durable but also ensures stability during operations, reducing vibrations and improving precision.

Each module (3D printer, laser engraver, and CNC) can be easily swapped out, allowing for a smooth transition between different modes. The modular approach also makes it future-proof, as Snapmaker often releases upgrades and accessories that can be added without replacing the entire machine.

The touchscreen control panel is another strong point in the design. It’s intuitive, easy to navigate, and well-integrated with the machine’s operations. The user can control everything from the touchscreen, from setup to monitoring real-time progress. This reduces the need for constant computer supervision.

However, the design does have a few drawbacks. The power module fan can be somewhat noisy, which might be distracting if you plan to run the machine in a quieter environment like a home office. Also, while the aluminum frame adds sturdiness, it also makes the machine relatively heavy, especially the larger models.

Assembly and Setup

The Snapmaker 2.0 comes as a DIY kit, which means some assembly is required. Fortunately, the assembly process is well-documented and straightforward, even for those new to DIY machines. The package includes everything you need, and the instruction manual is detailed, with step-by-step guidance and illustrations.

Depending on the model, the assembly can take anywhere from 1 to 3 hours. For beginners, this might be a bit daunting, but Snapmaker’s excellent customer support and comprehensive online resources can make the process smoother.

Once assembled, the setup is relatively painless. The machine auto-calibrates itself for 3D printing and laser engraving, although CNC work may require a bit more manual setup due to the need for precise measurements and bit changes.

3D Printing Performance

Snapmaker 2.0’s 3D printing capabilities are quite impressive for an all-in-one machine. The direct-drive extruder, heated bed, and auto-leveling feature contribute to a solid printing experience, allowing the machine to handle a variety of filament types, including PLA, ABS, TPU, and PETG.

Print Quality: The machine produces sharp and detailed prints, particularly in PLA. For larger prints, the A350 model’s expansive build volume is a huge advantage. Layer resolution is adjustable, allowing for both fast, low-quality prints and slow, high-detail jobs.

Printing Speed: Snapmaker 2.0’s printing speed is adequate, but it’s not the fastest on the market. It prioritizes precision over speed, which is a trade-off that might not appeal to users needing high-output machines.

Materials: While the machine can handle a variety of common filaments, it’s not ideal for more advanced or exotic materials like nylon or polycarbonate. For most users, however, the supported materials are more than sufficient.

Overall, Snapmaker 2.0’s 3D printing performance is commendable, especially given its hybrid nature. It competes well with dedicated mid-range 3D printers.

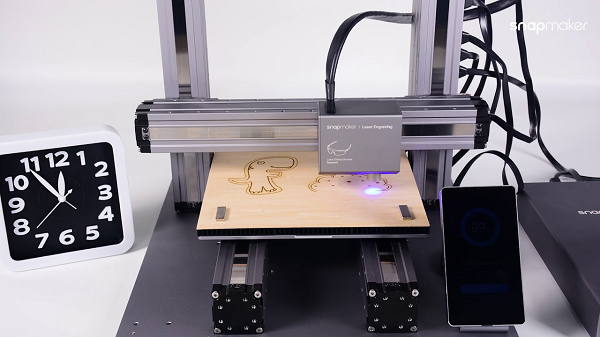

Laser Engraving and Cutting

Snapmaker 2.0 is also equipped with a 1.6W laser module that’s capable of engraving on materials like wood, leather, fabric, paper, and acrylic. The laser cutting function is more limited, only capable of cutting through thinner materials like paper and certain types of wood.

Laser Engraving Quality: The quality of engravings is excellent, with fine detail and good contrast. The autofocus feature helps to achieve consistent results, and the machine allows for both grayscale and vector engraving.

Laser Cutting: For laser cutting, the Snapmaker 2.0’s power is somewhat restricted. It’s good for thinner materials but struggles with anything thicker than 1.5mm wood or acrylic. Users looking for industrial-level laser cutting capabilities may need a more powerful dedicated machine.

One of the laser module’s key advantages is its safety features. Snapmaker includes laser protective shields and goggles, ensuring that users can work safely without risking exposure to harmful laser light.

CNC Carving

The CNC module is another highlight of the Snapmaker 2.0, designed for working with harder materials like wood, plastic, and even soft metals (such as aluminum). The module includes an ER11 collet, making it compatible with a wide range of bits, which gives users flexibility in the types of projects they can tackle.

CNC Performance: The CNC carving performance is strong for detailed work, particularly for engraving wood and plastics. The machine can achieve a high level of precision, and the sturdy build reduces vibrations that could compromise the quality of cuts.

Limitations: However, it’s not suitable for large-scale, heavy-duty CNC work. The spindle power, while effective for small to medium projects, isn’t strong enough for thick metal cutting or high-volume jobs. For hobbyists and small businesses focusing on engraving and light carving, though, it’s an excellent tool.

Software: Luban and Compatibility

Snapmaker’s proprietary software, Luban, is a unified platform that controls all three functions of the machine. It’s compatible with Windows, macOS, and Linux and offers an intuitive interface. Beginners will find Luban easy to use, but it also provides enough customization options for more experienced users.

For 3D printing, Luban is a competent slicing software with all the standard features, such as support structures, layer height adjustments, and infill options. For laser engraving and CNC carving, the software provides templates and presets, making it easy to get started.

However, more advanced users might find Luban somewhat limited, particularly for CNC work. The good news is that Snapmaker 2.0 is compatible with third-party software like Fusion 360 and Lightburn, giving users access to more powerful design and control tools if needed.

Pros and Cons

Pros:

- 3-in-1 versatility: Combines 3D printing, laser engraving, and CNC carving in one machine.

- High build quality: Sturdy aluminum frame reduces vibrations and improves precision.

- Modular design: Easy to switch between modules and future-proof with upgradable components.

- User-friendly touchscreen: Simplifies control and monitoring during projects.

- Good performance across all functions: Delivers solid results in 3D printing, laser engraving, and CNC carving.

- Excellent safety features: Especially for laser engraving, with shields and protective eyewear included.

- Luban software: Simple for beginners, but compatible with more advanced third-party software.

Cons:

- Assembly required: Can take a few hours to set up.

- Limited laser cutting power: Only effective on thin materials.

- Moderate CNC spindle power: Not suited for heavy-duty or large-scale CNC projects.

- Luban software: May be too basic for advanced users, particularly for CNC work.

- Noise: Power module fan can be quite loud during operation.

- Heavy machine: Larger models like the A350 can be difficult to move around.

Final Verdict

The Snapmaker 2.0 is a remarkable 3-in-1 machine, offering great value for makers who want versatility in a single device. Its performance in 3D printing, laser engraving, and CNC carving is impressive, though each function has its limitations. For those who require a multifunctional tool and are willing to compromise slightly on individual specialization, the Snapmaker 2.0 is an excellent choice.

While the machine might not replace dedicated tools in professional settings, it’s perfect for hobbyists, small business owners, and educational purposes.

Read Also

- Does Facebook Marketplace Ads Show in Google Organic Search?

- Is Johah Goldberg Part of Facebook Moderation

- TaxAct Login – How To Login TaxAct A Complete Guide

- What is Waterboy Movement In Stock Market

- What Is The Painting In Patrick Watson Spotify Page